Email

mahesh@ozagroupindia.com

Call

9890299999

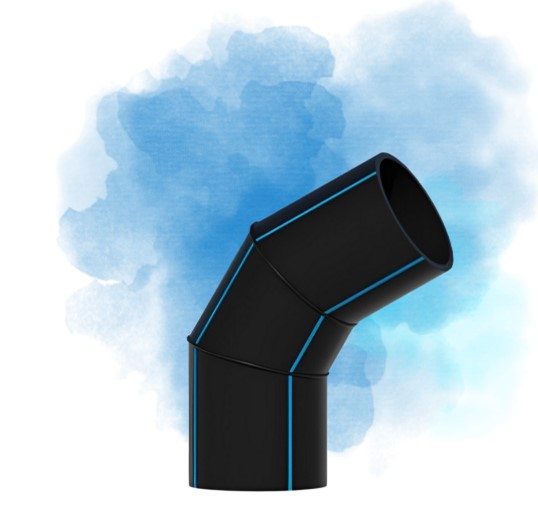

HDPE bends, commonly used in piping systems to change flow direction, offer several key features including flexibility, durability, and resistance to corrosion and chemicals. They are typically fabricated from high-quality HDPE material and designed for seamless integration with HDPE piping systems. These bends are available in various angles, such as 45 and 90 degrees, and can be joined using methods like butt fusion or electrofusion.

Durability

Flexibility

Corrosion and Chemical Resistance

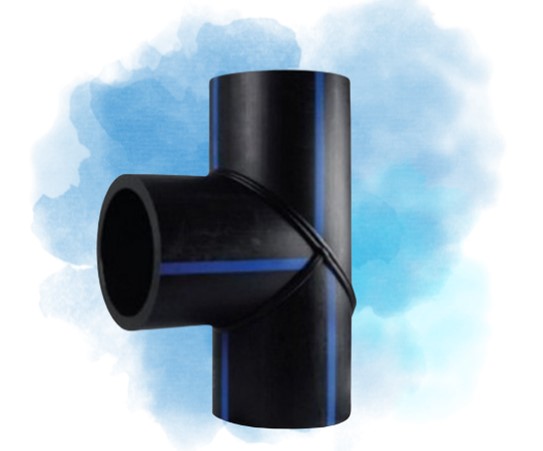

HDPE (High-Density Polyethylene) tees are T-shaped fittings used to connect three sections of pipe, creating a branch in the pipeline. They offer several key advantages due to the material properties of HDPE, including corrosion resistance, high strength, and flexibility. These features make them suitable for various applications like water supply, gas pipelines, and industrial fluid conveyance.

Durability

high strength

Leak-Proof Connections

Corrosion and Chemical Resistance

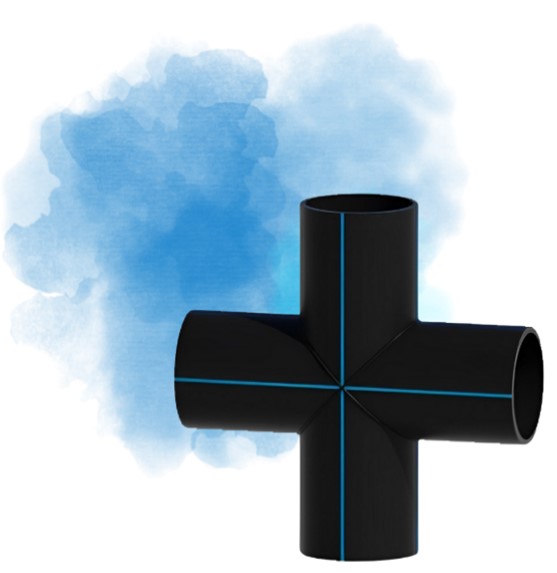

HDPE crosses, also known as HDPE cross fittings or HDPE cross tee, are four-way pipe fittings that connect four pipes at right angles. They are commonly used in various piping systems, including water supply, irrigation, and industrial applications, to efficiently distribute fluids. HDPE cross can effectively prevent drinking water pollution because it is sanitary, non-toxic, devoid of heavy metals and additives, difficult to scale.

High-Quality Material

Leak-Proof Connections

Durability and Long Service Life

Durability

An HDPE (High-Density Polyethylene) reducing tee is a pipe fitting that connects three sections of pipe, with one section being a different diameter than the other two, creating a branch connection while also reducing the pipe size. These tees are favored for their durability, resistance to corrosion and chemicals, and ease of installation, making them suitable for various applications, including water supply, gas distribution, and agricultural irrigation.

UV Resistance

Lightweight

Easy Installation

Low Maintenance